Sioux Center High School

The Bureau of Labor Statistics reports that welders have a bright job outlook in coming years. Sioux Center High School wanted to capitalize on this career path and asked Environmental Air Technology to create a solution to provide a Weld Shop, a Wood Shop, and a paint booth. This project is a great example of how we can provide a complete solution for a school wanting to expand their industrial technology opportunities.

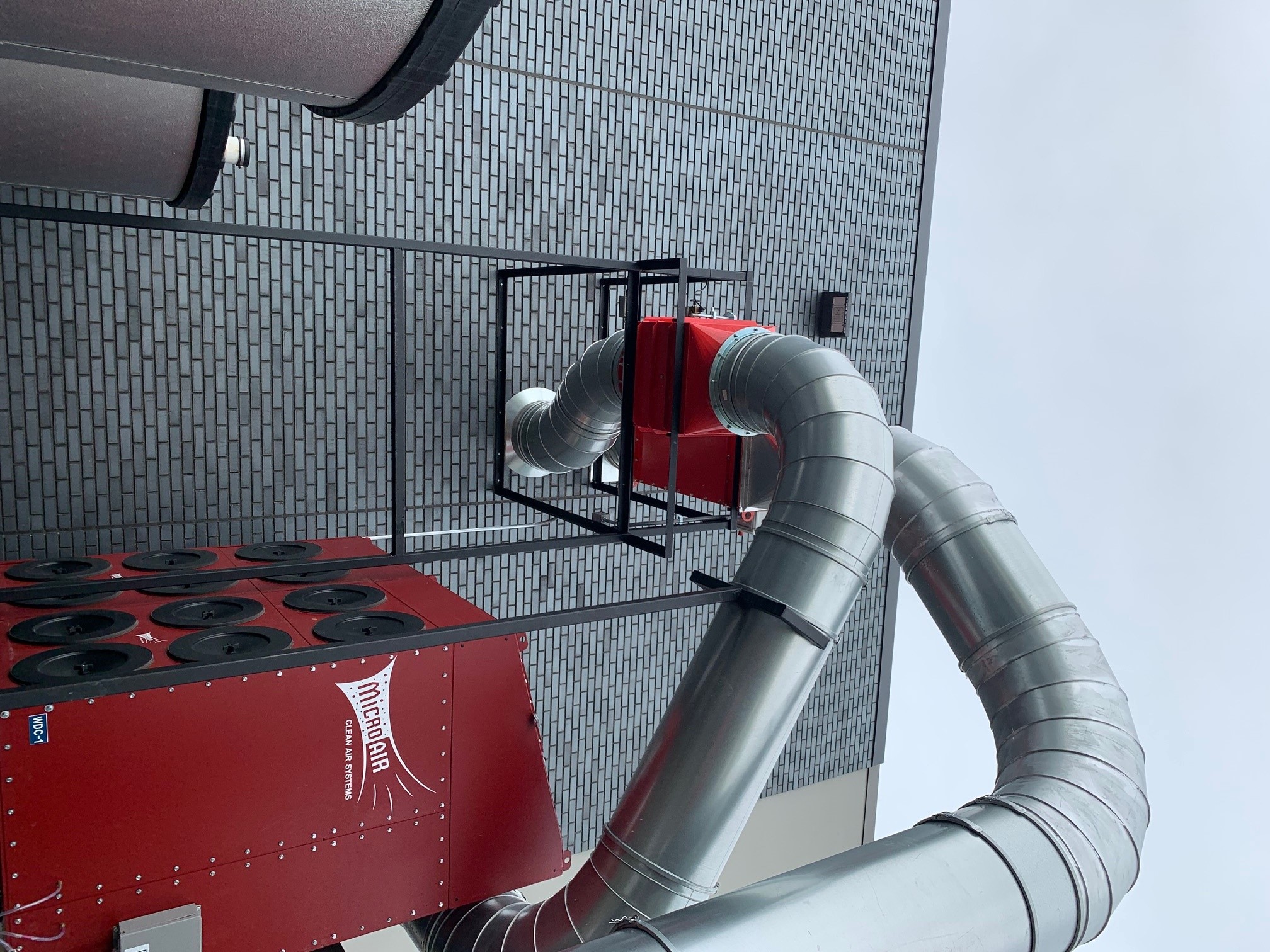

Wood Shop

The wood shop was designed with a Micro Air RP6 -12 Cartridge Dust Collector. The collector is equipped with top-mount explosion vents, high efficiency cartridge filters and ground mount GreenHeck Blower. This system provides 8,500 CFM.

This system is also equipped with:

- Duct mounted spark detection and spark extinguishing systems

- Explosion Isolation Damper on the negative air ductwork

- High speed abort gate on clean air duct work return to building

- Micro Air Intelli-touch panel with built in VFD that auto adjusts air volume dependent on filter loading

- NFPA 664,654,652 compliant

Weld Shop

The weld shop was designed with the following:

- 10 Micro Air XA23 Downdraft Tables designed to capture weld fume and particulates before entering the student breathing zone. These self-cleaning units will provide 2 years of filter life.

- 2 Micro Air TM1000 Portable Downdraft Units to capture weld fume being produced outside of the weld booths

Paint Booth

- The paint booth was designed with a Rohner bench style booth.

- The spray booth includes paint overspray filters, Class II, Div. 2 light fixtures and a rooftop Greenheck Make-up air unit.

A project success story for Sioux Center High School, starting the school year with technical opportunities for their students. Win-win for all! – another Clean Air, Breath Easy solution.